CAMSENS Applications

and more

Indoor Air Measurement

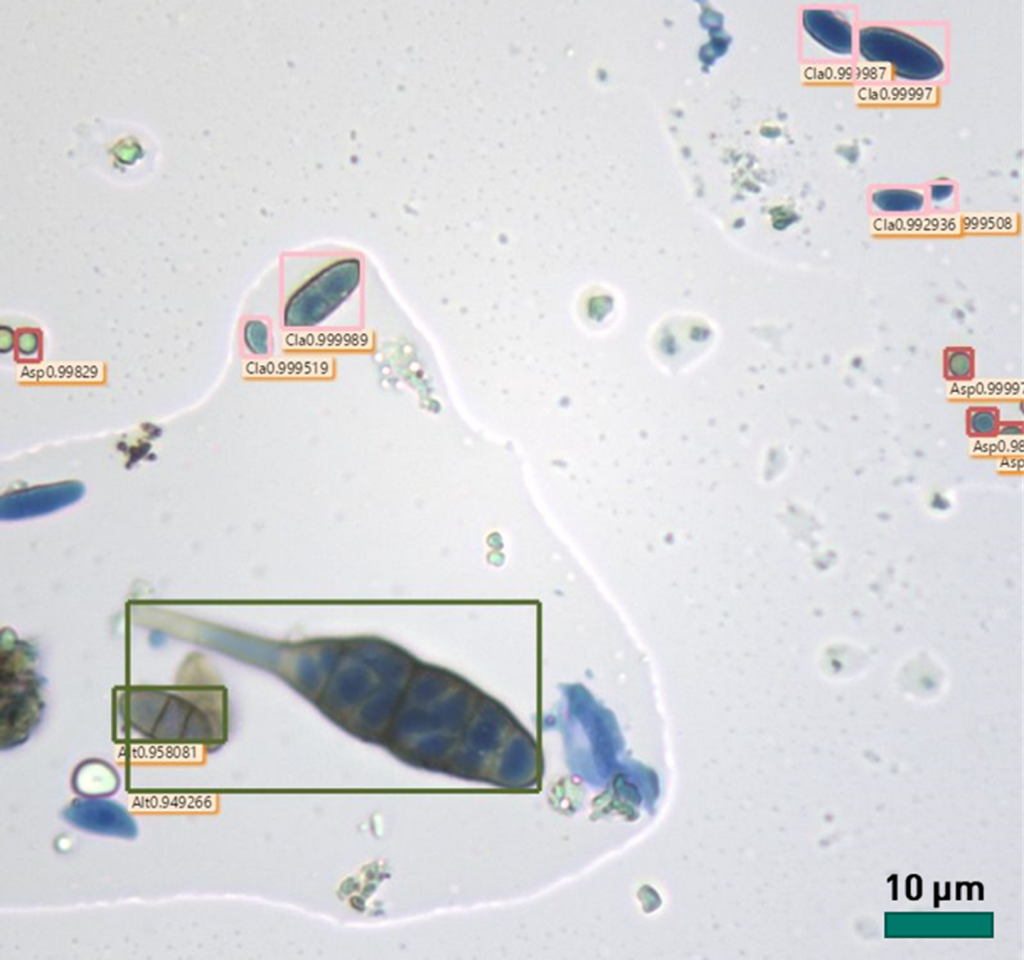

Airborne particles such as mold spores can cause health issues and compromise the safety of workplaces and industries. CAMSENS offers fast, fully automated solutions for particle analysis and quality control with our innovative technology. We offer measurement devices that can be used mobile, in laboratories, or integrated across the enterprise, expanding the connectivity to accelerate responses when issues are identified. Furthermore, we attend to the growing demand for personalized products by adapting our software to recognize relevant particles for your business.

We have been already successfully approved in the interlaboratory survey conducted by the German Association of Building Biology (13. VDB–Ringversuch) in 2019, meaning that our software and measurement devices can effectively detect and recognize spores.

Food Industry

In the food industry, airborne particles can contaminate the processing facilities and lead to food spoilage and production loss, in addition to causing health issues to consumers and workers. There is a need for real-time monitoring and identification of specific particle contaminants, such as mold, spores, and bacteria.

CAMSENS offers ready-to-use devices for the analysis of airborne particles that could contaminate the food industry. Our systems use fully automated, high-resolution microscopes, as well as state-of-the-art deep learning algorithms for object recognition, to ensure detailed analysis in just a few minutes.

Pharmaceutical industry

In the pharmaceutical industry, cross-contamination could be strongly prevented by the early and precise detection of active pharmaceutical ingredients (APIs) originated from the production of different medicaments in the same factory. Most APIs are in the micrometer range and, thus, can be detected by cameras and sensors systems. Our deep-learning software can provide individualized and customized solutions.

Research and Development (R&D)

We strongly value the importance of research and development and believe it is the first step towards innovation. We are willing to cooperate with companies, research institutes, and universities in R&D projects where our technologies apply. This includes the further development of our particle analysis devices and the use of camera-based technologies for product quality and control, for example. We have vast experience in working with funding programs as DFG, AiF, or ZIM. We are happy to discuss further project possibilities with you. Contact us.

Production line and object inspection

The production line control is a key step to guarantee the quality and safety of products. There are needs for fast, intelligent, and real-time monitoring related to product inspection, defect recognition, or functionality of the product line itself to make sure the final product meets the quality needs of your customers.

The inspection and associated object recognition can be done based on dimensions, morphology, or color. Depending on the industry segment, other responses types, such as sensorial or voltage difference, can guarantee the control you need. Each industry and production line have their own set of manufacturing issues. We incorporate a range of solutions from non-contact, visual inspection to electronics system solutions to attend every industry segment.

Industry 4.0

The industrial digital transformation needs adaptable and often customer-specific solutions that provide fast answers and can be integrated into existing machines/software/programs. The intelligent image recognition, sensors, and deep-learning algorithms proposed by CAMSENS offer flexibility and strategic competitive advantages by increasing product quality and workplace safety resulting from real-time monitoring.

We solve the current market gap regarding fast, intelligent, and fully automated analysis of products to ensure the manufacturing and environmental quality and safety of our customers within the context of Industry 4.0.

Smart Green Technology

Nowadays, sustainability is a key topic in industrial production. The requirement for green technologies is maturing fast and it is challenging for organizations to adapt to these changes. However, it is necessary if they want to survive in the near future. Energy management is one of the first approaches to consider when talking green. Besides protecting the environment, it is associated with reduced costs and improved performance.

CAMSENS contributes to improving the energy management and efficiency of your business by developing smart and automated solutions for product control. With our deep know-how in electronics and innovative technologies, we bring your production a step closer towards digital transformation and green technologies.

We are happy to help you find the best solution for you.